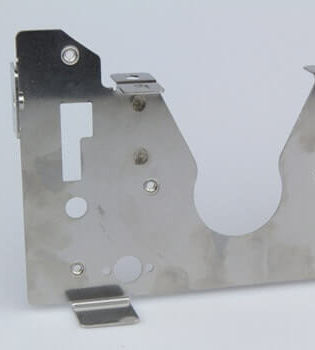

The precision and strength of sheet metal manufacturing depend on the sheet metal forming, cutting and assembly processes. The resulting product is rugged and able to withstand wear and tear as well as extreme conditions. The durability and strength of sheet metal fabricated products are critical to ensuring their longevity and reliability, making them suitable for a variety of industrial, commercial and consumer applications.

Sheet metal fabrication plays a vital role in modern industry, contributing to various industries and enabling the production of a variety of products. This versatile manufacturing process involves shaping, cutting and manipulating thin sheets of metal to create components and structures.

Automotive Industry: It is used in the manufacture of body panels, chassis and other structural components. The precision and durability of sheet metal fabrication make it ideal for creating parts that can withstand the rigors of the automotive environment.

Construction: Sheet metal fabrication is critical for HVAC systems, ventilation ducts, and roofing materials. The ability to manufacture custom and precise components allows for efficient and effective installations, thereby increasing a building's energy efficiency and comfort.

Other industries, such as furniture manufacturing, signage production and kitchen appliance manufacturing, also benefit from sheet metal fabrication. Its ability to produce custom designs, cost-effectiveness, and durability make it a popular choice for manufacturing a variety of products.

Sheet metal fabrication offers versatility in mechanical design. It allows designers to create a variety of complex shapes and forms, enabling the production of complex and functional parts. Whether it’s an enclosure, bracket or panel, sheet metal fabrication provides the flexibility needed to meet specific design requirements.

Additionally, sheet metal manufacturing is great for strength and durability. By using strong metals such as steel or aluminum, the resulting components can withstand rigorous mechanical stresses and environmental conditions. This makes sheet metal fabrication ideal for applications requiring robustness and longevity.

The cost-effectiveness of sheet metal fabrication is another significant advantage. The process makes efficient use of materials, minimizing waste and reducing production costs. Additionally, the ability to fabricate mass-produced components using sheet metal makes it a cost-effective solution for mechanical design projects.

Sheet metal fabrication is a fundamental process that plays a key role in industrial design. It involves transforming sheet metal into a variety of components and structures used in a wide range of industries. This versatile process gives designers the flexibility and precision they need to turn ideas into reality.

Using sheet metal fabrication in industrial design enables the creation of complex shapes. As technology advances, designers can achieve precise bends, curves, and angles to create unique and visually appealing products. Whether it's a sleek, modern structure or a functional device, sheet metal fabrication can turn design ideas into reality.

Sheet metal fabrication is built for strength and durability, and using strong metals such as stainless steel or aluminum ensures the final product can withstand harsh industrial environments. This makes sheet metal fabrication ideal for applications requiring structural integrity and reliability.

Additionally, sheet metal fabrication provides designers with the flexibility to create custom designed components. Whether it's a specialized enclosure, unique fixtures or custom parts, sheet metal fabrication can meet the specific needs of an industrial design project. This customization capability allows for the creation of products that meet precise specifications and functional requirements.

Sheet metal fabrication involves precision cutting, shaping and assembling sheets of metal to produce structurally sound parts. This process ensures even stress on the metal, providing greater strength and durability. This makes sheet metal fabrication ideal for structural applications requiring longevity and reliability.

Sheet metal can be formed into a variety of configurations, allowing for a high degree of customization and design flexibility. Whether it is a load-bearing structure, shell or frame, sheet metal fabrication provides the means to create customized solutions that meet specific requirements.

Sheet metal fabrication is often more cost-effective than other manufacturing methods. It involves relatively simple tools and processes, resulting in lower production costs. Additionally, sheet metal is a widely available material that is easier to source and purchase in bulk, further reducing overall costs.

RMT is a precision custom manufacturing provider. We provide high-quality manufacturing with on-time delivery at competitive prices. Express your requirements and once confirmed, we will develop a solution that satisfies you. Every step in the process We will continuously communicate with you at every stage so that you can understand all the information about product manufacturing.

Put the needs and expectations of customers first and center, customize satisfactory solutions with personalized services for them, and exceed customers' expectations, thereby cultivating reliable long-term trust relationships.

Guiding clients through the custom manufacturing process from concept to completion, our consultants work closely with each client to understand their unique specifications and provide strategic insights for personalized production solutions

We utilize state-of-the-art machinery and strict quality control measures to manufacture components to precise tolerances. Every part undergoes rigorous inspection to ensure micron-level accuracy to meet the most demanding specifications.

From raw materials to finished products, we meticulously adhere to strict standards, monitoring and testing every step using cutting-edge methods to guarantee consistent performance and durability in all our products.

Sheet metal fabrication is a manufacturing process that involves shaping, cutting, and forming thin sheets of metal into desired components or structures. It typically includes processes like cutting, bending, welding, and assembly.

Sheet metal fabrication uses precise measurement, CAD/CAM software, and CNC machinery to ensure accurate cutting, bending, and forming of the metal sheets.

Design considerations include material selection, appropriate bend radii, tolerances, nesting of parts for efficient material usage, and consideration of manufacturing processes.

Sheet metal fabrication offers advantages such as high precision, excellent strength and durability, cost-effectiveness, design flexibility, and scalability for different production volumes.

Laser cutting uses a high-powered laser beam to cut through the metal with precision, while traditional cutting methods involve mechanical cutting tools such as shears or saws.

Common finishing techniques include deburring, grinding, polishing, powder coating, painting, and plating to improve aesthetics and protect against corrosion.