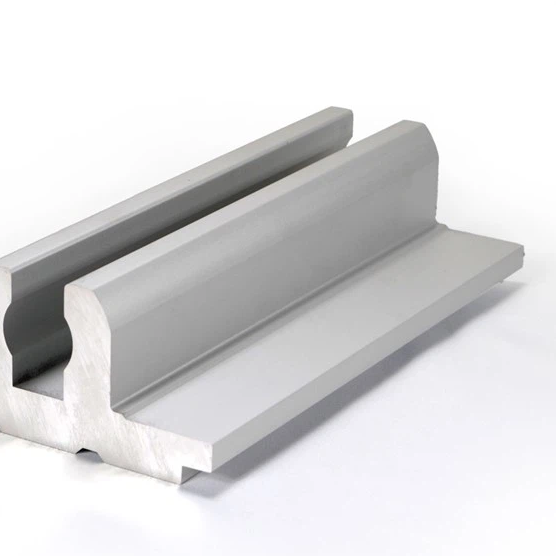

By applying high pressure and temperature, extrusion technology transforms metals such as aluminum and alloys into strong and lightweight continuous and precisely shaped parts. Extruded parts provide consistent dimensional accuracy and tolerances, ensuring seamless integration within the assembly. , and minimize waste from rework or scrap.

The versatility of profiles allows manufacturers to create complex geometries and hollow profiles that can be easily adapted to a variety of applications, simplifying logistics and speeding up assembly lines. Additionally, the inherent strength of extruded parts often eliminates the need for additional reinforcements, helping to produce a lighter, more efficient end product.

RMT is a precision custom manufacturing provider. We provide high-quality manufacturing with on-time delivery at competitive prices. Express your requirements and once confirmed, we will develop a solution that satisfies you. Every step in the process We will continuously communicate with you at every stage so that you can understand all the information about product manufacturing.

Put the needs and expectations of customers first and center, customize satisfactory solutions with personalized services for them, and exceed customers' expectations, thereby cultivating reliable long-term trust relationships.

Guiding clients through the custom manufacturing process from concept to completion, our consultants work closely with each client to understand their unique specifications and provide strategic insights for personalized production solutions

We utilize state-of-the-art machinery and strict quality control measures to manufacture components to precise tolerances. Every part undergoes rigorous inspection to ensure micron-level accuracy to meet the most demanding specifications.

From raw materials to finished products, we meticulously adhere to strict standards, monitoring and testing every step using cutting-edge methods to guarantee consistent performance and durability in all our products.

The extrusion process enhances the strength of extruded parts through several mechanisms. Firstly, the process involves forcing the material through a die, which imparts directional grain flow, resulting in improved mechanical properties. Secondly, the uniformity and homogeneity of the extruded profiles contribute to consistent material properties throughout the part, ensuring reliable strength and performance.

When utilizing extrusion parts, designers should consider factors such as wall thickness, cross-sectional geometry, and structural integrity. Wall thickness should be optimized to achieve a balance between strength and weight. Cross-sectional geometry should be designed to meet specific functional requirements, such as load-bearing capabilities or fluid flow channels. Structural integrity should be ensured through appropriate support structures and connections.

Extrusion parts offer several cost-effective advantages. Firstly, the continuous extrusion process enables the production of large volumes of parts in a short span of time, reducing production costs. Secondly, the high material utilization rates in extrusion minimize material waste, further reducing costs. Additionally, the ability to extrude a wide range of materials allows manufacturers to choose cost-effective options without compromising performance.

Extrusion parts offer design flexibility, streamlined production processes, material efficiency, cost-effectiveness, and consistent quality. These advantages contribute to improved productivity and enhanced performance in various industries.

The extrusion process minimizes material waste by utilizing continuous production methods and producing near-net shapes. Precise control over material flow ensures high material utilization rates, reducing waste and optimizing material efficiency in manufacturing processes.