How to Choose the Right Precision Sheet Metal Fabricator for Your Projects

Understanding Precision Sheet Metal Fabrication

Sheet metal fabrication done with precision is actually one of those advanced manufacturing methods that really matters when making complicated metal parts for all sorts of purposes. The process basically cuts, bends, then puts together thin sheets of metal until they match very specific measurements required by engineers and designers. Because these fabricated pieces need to fit perfectly into larger assemblies, manufacturers rely heavily on this method across multiple sectors from automotive to aerospace. What makes it so valuable? Well, aside from getting things right dimensionally, the resulting parts tend to last longer too while looking pretty good aesthetically speaking. That combination explains why many companies just can't do without proper sheet metal work when building anything that needs structural integrity combined with visual appeal.

A lot of different sectors depend on precise sheet metal work these days. Think about aerospace for instance they make all sorts of critical parts using this technique, something that's helping their industry grow fast. Market analysts predict it could hit roughly 838 billion dollars in value by 2026. The auto manufacturing world also gets a lot out of this kind of fabrication when making vehicle frames and housing units for electronics inside cars. As our global communications systems expand and we keep buying more gadgets, there's even greater need for accurate sheet metal work in telecom and electronics fields. This helps build those tough, reliable parts needed for everything from cell towers to smartphone cases that can withstand daily wear and tear.

Techniques in Precision Sheet Metal Fabrication

Sheet metal fabrication requires a range of sophisticated methods, and among them stands out CNC or Computer Numerical Control machining. What makes CNC so valuable is its ability to maintain both precision and consistency across multiple parts. The process works by linking computer systems directly to cutting and forming tools, which means every piece comes out exactly the same way each time. Industry data shows these machines can hit tolerances down to 0.0005 inches – that's about the thickness of a human hair. For manufacturers working on complex projects where even tiny deviations matter, this level of accuracy turns CNC machining into an essential tool in their workshop arsenal.

Laser cutting stands out as one of the key technologies used in modern sheet metal work. The process works by directing a powerful laser beam at metal sheets, allowing for cuts that are both accurate and efficient. When compared against older cutting techniques, lasers cut about 20 times quicker than conventional methods. They also create less scrap material and cause minimal thermal damage to surrounding areas. For manufacturers needing complex components with tight tolerances, laser cutting has become essential across industries ranging from aerospace to automotive manufacturing where precision matters most.

Sheet metal fabrication relies heavily on welding techniques, particularly TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding which dominate the industry. TIG stands out because it offers incredible precision and control, so it works really well when dealing with thin gauge metals or situations where clean, high quality welds are absolutely necessary. On the flip side, MIG welding gets the job done quicker and handles thicker materials much better than TIG does, especially in mass production settings. When deciding between these two approaches, fabricators need to consider what kind of material they're working with and exactly what the finished product needs to do. Both methods showcase how flexible sheet metal fabrication can be across different industries, from aerospace components to everyday appliances we use at home.

Choosing the Right Precision Sheet Metal Fabricator

When looking for a precision sheet metal fabricator, experience matters a lot. Start by checking how long they've been around in business. Most companies that have operated for at least two decades tend to build up solid reputations over time. Take a look at what kind of work they've done before too. Case studies give some idea about whether they can tackle similar jobs to what we need. Client feedback is pretty valuable as well. What do past customers actually say about working with them? Do they mention things like showing up on time or delivering quality products? All these pieces together tell us if the fabricator can really deliver what our business needs without all the headaches.

When picking a fabricator, quality assurance matters a lot too. Look for shops that have solid QA systems in place. Many good ones will carry ISO 9001 certification, which actually means something real world. This certification shows they're serious about keeping their production up to snuff so their stuff meets what customers want and what regulations demand. Why does this matter? Well, when a shop maintains tight quality controls, there are fewer mistakes in the final product. Customers get what they paid for without surprises later on because the work stays consistent from job to job.

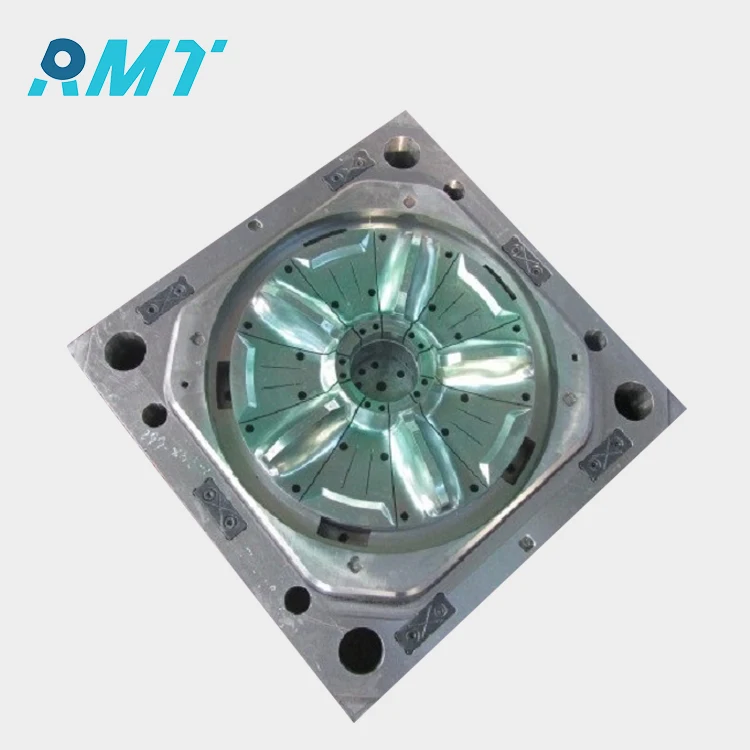

Sheet metal fabrication really depends on good equipment these days. Shops that have invested in modern CNC machines along with laser cutting systems tend to produce much better results. These tools cut down on mistakes made by hand and waste less material overall. What this means for actual shop work is that complex parts get made correctly first time around while production runs finish quicker too. The bottom line? Less money spent on rework and happier customers getting their orders sooner. When looking for reliable fabrication services, companies would do well to check if the shop uses current tech rather than relying on older methods that just don't measure up anymore.

Key Factors to Consider

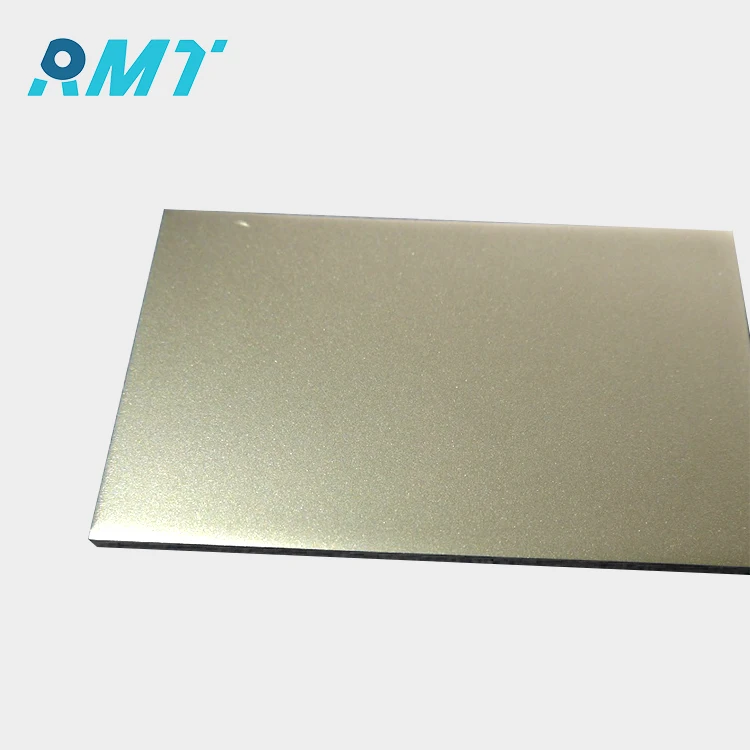

Material choice matters a lot in precision sheet metal work because it directly impacts how long something lasts and what it can actually do. Different metals bring their own set of characteristics to the table regarding things like how they handle stress, heat resistance, and reactions to chemicals. Take aluminum for example it's often the go to option when weight savings are important, whereas steel gets picked when extra toughness is needed. Then there's also the question of money and timing. Some materials just aren't readily available at certain times, which can really throw off production schedules. And let's face it, budget constraints force manufacturers to weigh options carefully before making commitments.

The application of Design for Manufacturability (DFM) concepts really makes a difference when it comes to running operations smoothly while keeping those production expenses down. When engineers think about how things will actually be made during the design stage itself, they tend to catch problems before they become expensive headaches later on. Good DFM practices result in products that work well in real world manufacturing settings without breaking the bank. The benefits include better use of raw materials, easier assembly processes, and less scrap ending up in landfills. Many companies have seen significant savings just by incorporating these basic but powerful design considerations from day one.

When choosing a fabricator for any given project, turnaround time and production capacity matter quite a bit. Whether or not a shop can stick to deadlines really affects how long the whole project takes to complete. Production capacity tells us if they're able to manage everything from tiny jobs to big scale work without breaking a sweat. Fabricators who have updated equipment generally produce better results too. The right machines mean greater accuracy and faster work overall, which keeps things moving along without compromising on quality standards for the finished product.

Popular Products from Leading Fabricators

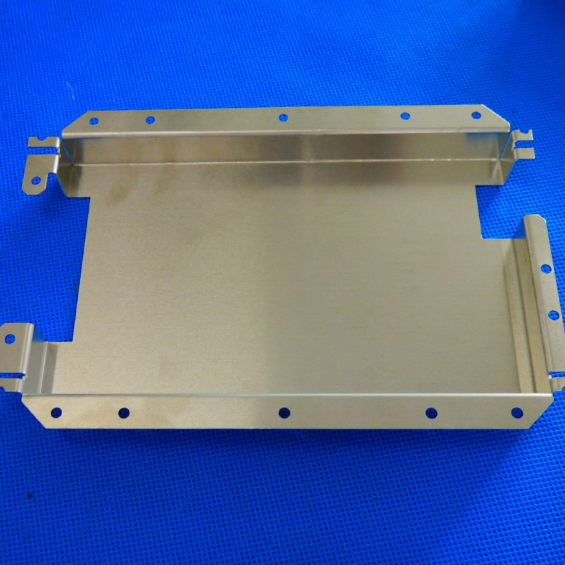

Top sheet metal shops keep turning out those common parts we see everywhere, spanning everything from car bodies right through to airplane parts. What makes these components so valuable is their precise manufacturing and dependable performance, which matters a lot when making things like surgical tools or housing for electronics. Take cars for example. Sheet metal work remains absolutely vital there too, creating all sorts of tough parts including frames and mounting hardware that hold vehicles together.

High precision CNC machining gives fabricators the ability to create custom sheet metal bends that fit exact specifications. We see this in action when making computer cases from aluminum alloys. Each casing gets built specifically for what the customer needs, which matters a lot for how well heat moves through the system. The structural strength also improves because everything fits together just right. For companies working on complicated computing setups, these tailored solutions make all the difference in performance and reliability over time.

When it comes to making custom parts for machines using CNC technology, these components are really important for putting together bigger systems in lots of different sectors from automotive to aerospace. The manufacturing involves things like milling and turning operations that make sure every single part works properly when assembled. Take medical equipment for example the tiny connectors and fittings need to be made with extreme accuracy because hospitals have strict rules about what qualifies as safe and effective. A small error here could mean big problems down the line.

The demand for customized processing, particularly in stamping stainless steel for products like long door lock parts, reflects a broader market need for robust and reliable security solutions. Fabricators address this demand by employing advanced stamping techniques to produce parts that withstand long-term use while ensuring superior performance.

Sheet metal fabrication shops offer all sorts of custom made products that fit what various industries need. Take aerospace for instance where they need parts that are both light weight but still super strong. Manufacturers can actually create these specialized components right down to the last detail. When fabricators focus on what each sector specifically requires, it opens up new possibilities for how metal products get used across different applications. This approach means better solutions for clients while expanding where these metal parts might be applied in real world situations.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

LV

LV

SR

SR

SK

SK

UK

UK

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

EU

EU

BN

BN

BS

BS

LA

LA

NE

NE

SO

SO

KK

KK