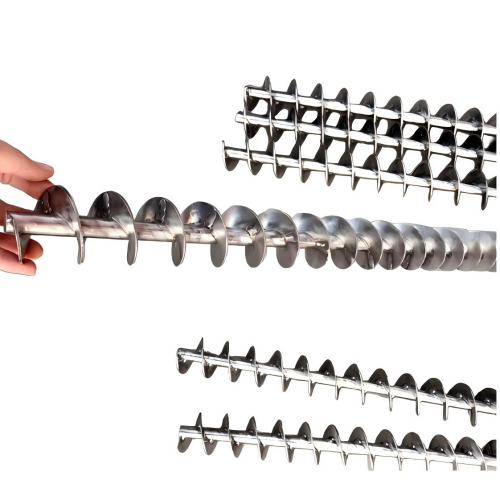

Custom Precision Machining Stainless Steel Spiral Blade

Our stainless steel spiral blades are precision-engineered for smooth and efficient material handling in demanding industries such as food processing, mining, and agriculture. They are customizable in size, pitch, and material, ensuring durability, minimal maintenance, and consistent performance. Partner with us for reliable OEM solutions and large-volume orders.

- Overview

- Inquiry

- Related Products

- Material: Carbon steel (Q235), stainless steel (SS304/SS316L), or manganese steel, customizable based on corrosion/abrasion requirements.

- Process: Cold-rolling (for seamless blades ≤5mm) or hydraulic stretching (for thicker blades 5–40mm), reinforced with nickel-chromium alloy surfacing.

- Key Advantage: 30% longer lifespan with wear-resistant surfaces, customizable pitch/diameter for efficient material flow.

- Precision: Pitch and diameter controlled within ±0.1mm via CNC-guided formin.

- Tolerance: Critical dimensions (e.g., outer diameter) held to ±0.1mm standards.

- Surface Finish: Polished (food-grade smoothness) or sandblasted for corrosion resistance.

- Prototype Lead Time: 5–10 days with drawings.

- Mass Production Lead Time: 15–30 days after approval.

- Outcome: Blends mixing and conveying with 15–20% energy reduction, minimal clogging.

Process Flow:

Our mixing and conveying spiral blades are defined by precision forming and wear-resistant treatment processes:

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

LV

LV

SR

SR

SK

SK

UK

UK

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

EU

EU

BN

BN

BS

BS

LA

LA

NE

NE

SO

SO

KK

KK