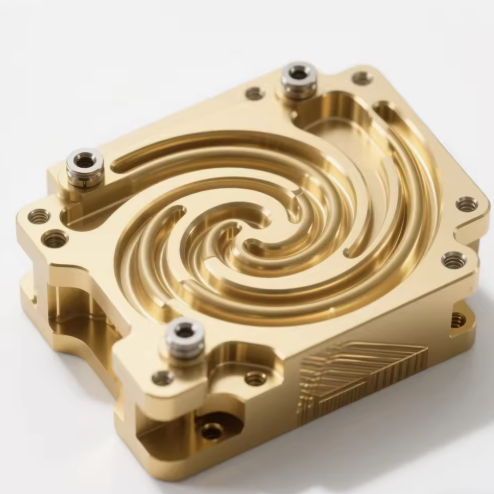

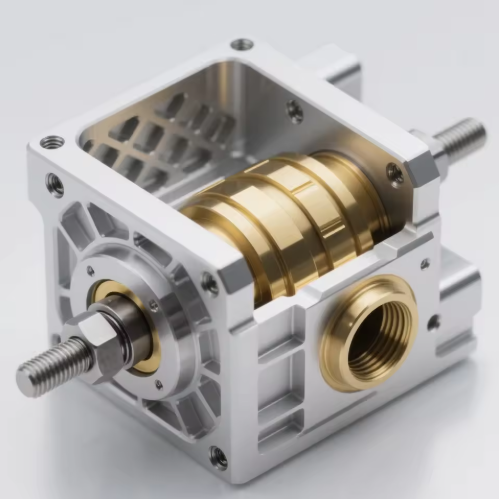

Custom Precision Aluminum Alloy Aircraft Model Drive

Designed for high-torque and smooth operation in aircraft models, this custom precision aluminum alloy drive component delivers outstanding performance. We specialize in high-quality, tailored machining solutions to meet your exact specifications and ensure reliability. Ideal for projects requiring dependable, high-volume custom manufacturing. Contact us to discuss your needs.

- Overview

- Inquiry

- Related Products

- Material: High-strength aluminum alloy 7075-T6.

- Process: 5-Axis CNC Milling.

- Key Advantage: Achieves optimal strength-to-weight ratio with complex, weight-saving geometries for enhanced model performance..

- Precision: Tooth profile accuracy up to ISO 9001, pitch deviation ≤0.01mm.

- Tolerance: Strictly controlled within ±0.01mm.

- Surface Finish: Standard roughness Ra 0.6, with options for anodizing (color customization), sandblasting, or PTFE coating.

- Prototype Lead Time: 3-7 days.

- Mass Production Lead Time: 2-3 weeks (with batch packaging and logistics tracking).

- Outcome: Delivers higher transmission efficiency, operational reliability, and extended service life for aircraft models.

Process Flow:

Our aircraft model drive components are manufactured through precision 5-Axis CNC Machining and strict quality control:

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

LV

LV

SR

SR

SK

SK

UK

UK

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

EU

EU

BN

BN

BS

BS

LA

LA

NE

NE

SO

SO

KK

KK