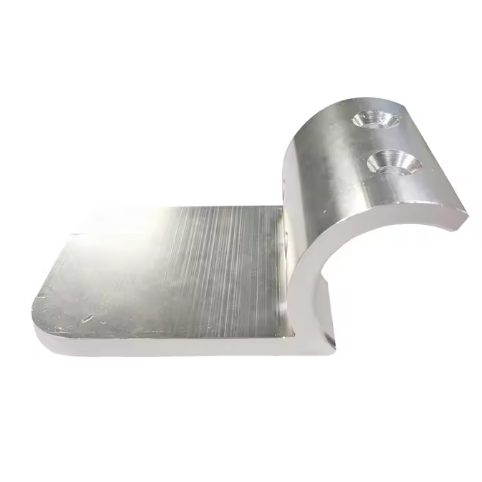

Custom CNC Machining Shelf Support Bracket

This shelf support bracket is engineered for reliability through custom CNC machining. It offers high load-bearing capacity and is adaptable to your specific design requirements. Available in various metals and surface finishes, it ensures a secure and long-lasting solution for diverse shelving applications.

- Overview

- Inquiry

- Related Products

- Material:High-strength aluminum alloys(e.g.,6061-T6,7075),stainless steel(e.g.,304,316),or other metals customized to requirements.

- Process:Multi-axis CNC milling and turning,integrated with drilling and tapping processes,enable monolithic formation of complex structures.

- Key Advantage:High strength-to-weight ratio with customizable lightweight geometries;easy installation compatible with furniture,storage,and display systems.

- Precision:Micron-level machining accuracy ensures dimensional stability and structural integrity.

- Tolerance:Tight tolerances within±0.01 mm to±0.1 mm(adjustable per requirements).

- Surface Finish:Surface roughness of 0.8 Ra,with options for anodizing,plating,sandblasting,or powder coating to improve corrosion resistance.

- Prototype Lead Time:1–7 working days(adaptable to design complexity).

- Mass Production Lead Time:1–3 weeks(production schedule optimized for order volume).

- Outcome:Deliver structurally robust,dimensionally precise brackets that enhance load-bearing capacity and safety of shelf systems,extending service life.

Process Flow:

Our shelf support brackets are engineered for durability and precision through advanced CNC machining.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

LV

LV

SR

SR

SK

SK

UK

UK

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

EU

EU

BN

BN

BS

BS

LA

LA

NE

NE

SO

SO

KK

KK