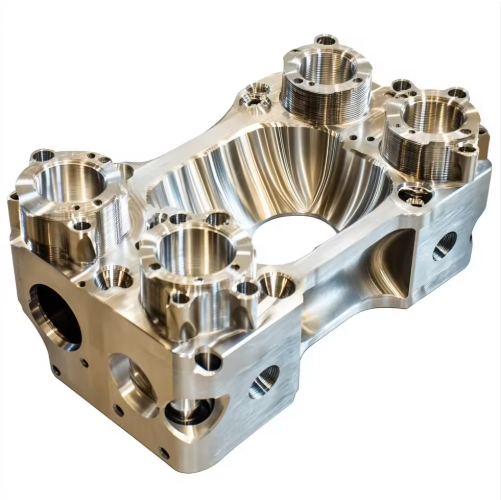

Custom CNC Machining Aircraft Engine Aluminum Part

We provide custom CNC machining services for critical aircraft engine components. Our expertise lies in transforming high-grade aluminum alloys into complex, lightweight, and durable parts that meet rigorous aerospace standards. From prototype to production, we ensure each piece achieves precise dimensions, excellent surface finishes, and flawless functionality for optimal engine performance.

- Overview

- Inquiry

- Related Products

- Material:High-strength aluminum alloy 7075-T6.

- Process:5-axis CNC machining.

- Key Advantage:High strength-to-weight ratio; resistant to high temperatures and corrosion; ideal for critical engine components..

- Precision:Micron-level accuracy (up to ±0.01 mm).

- Tolerance:±0.01 mm.

- Surface Finish:Smooth anodizing or powder coating (Ra ≤ 0.6 μm).

- Prototype Lead Time:1–5 working days.

- Mass Production Lead Time:1–2 weeks (depending on order quantity).

- Outcome:Durable, lightweight engine components that enhance safety, reduce fuel consumption, and extend service life.

Process Flow:

This product is a high-precision aluminum alloy component designed for aircraft engines, featuring complex geometries with multiple bore holes, grooves, and cavities.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

LV

LV

SR

SR

SK

SK

UK

UK

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

EU

EU

BN

BN

BS

BS

LA

LA

NE

NE

SO

SO

KK

KK