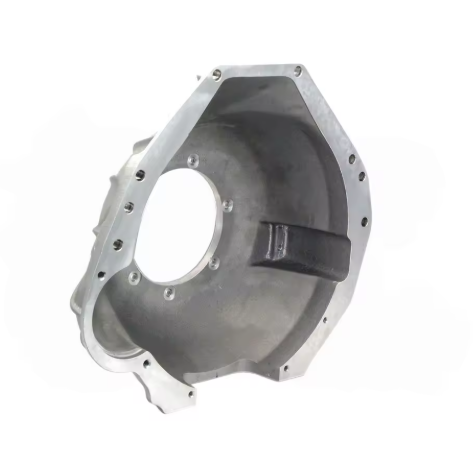

Custom CNC Aluminum Bell Housing for Aerospace Hydraulic Systems

Our aerospace-grade CNC aluminum bell housing connects motors and hydraulic pumps precisely. Made from high-strength aluminum alloy, it uses 5-axis machining for alignment, is lightweight, durable and corrosion-resistant. It's customizable to meet specifications and ensures reliable performance in demanding aviation applications.

- Overview

- Inquiry

- Related Products

- Material: High-strength aluminum alloys (e.g., 6061-T6, 7075), optimized for aerospace applications.

- Process: 5-axis CNC milling and turning, ensuring complex geometries are achieved in a single setup.

- Key Advantage: Lightweight yet robust design reduces overall system weight while maintaining high torque capacity and heat resistance.

- Precision: Critical features machined to IT8 grade standards, with surface roughness up to Ra 0.4μm.

- Tolerance: Tight tolerances within ±0.01 mm for critical dimensions, ensuring seamless integration.

- Surface Finish: Anodizing for enhanced corrosion resistance, with optional bead blasting or polishing.

- Prototype Lead Time: 3–5 working days for rapid prototyping.

- Mass Production Lead Time: 15–20 working days for bulk orders.

- Outcome: High durability, reduced vibration, and extended service life under extreme aerospace conditions.

Process Flow:

Our aluminum bell-shaped housing for aviation hydraulic systems is defined by a precise CNC machining process.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

LV

LV

SR

SR

SK

SK

UK

UK

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

EU

EU

BN

BN

BS

BS

LA

LA

NE

NE

SO

SO

KK

KK