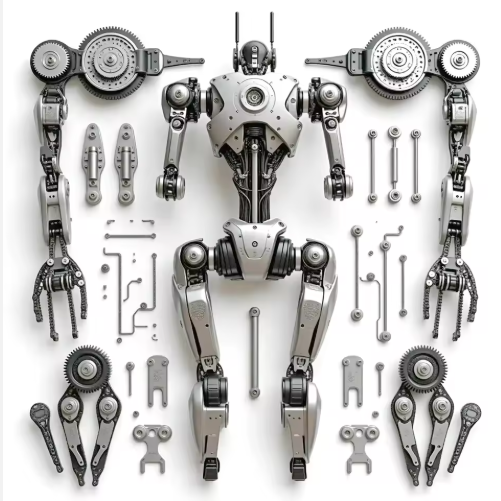

Vlastní přesné obrábění ramene robotu z hliníkové slitiny

Zvyšte úroveň vaší automatizace s našimi speciálně vyrobenými robotickými rameny. Vyfrézovaná z vysoce pevné hliníkové slitiny nabízejí výjimečnou přesnost a odolnost pro náročné průmyslové úkoly. Ideální pro výrobce zařízení nebo integrační společnosti hledající spolehlivé součásti pro automatizaci s vysokým výkonem.

- Přehled

- Dotaz

- Související produkty

- Materiál: vysoce pevná hliníková slitina 7075-T6.

- Zpracování: 5osé CNC obrábění a přesné frézování.

- Klíčové výhody: optimální poměr pevnosti k hmotnosti, vysoká tuhost a možnost vytvářet komplexní konstrukce šetřící hmotnost.

- Přesnost: opakovaná přesnost polohování: ±0,05 mm (na základě servomotoru se zpětnou vazbou a vysokopřesných reduktorů).

- Tolerance: ±0,01 mm.

- Úprava povrchu: drsnost povrchu Ra 0,4, volitelné tvrdé anodování nebo PTFE povlakování pro zvýšení odolnosti proti opotřebení a korozí.

- Doba výroby prototypu: 1–5 dnů (na základě potvrzeného 3D modelu).

- Doba výroby na velké množství: 2–3 dny (v závislosti na objednaném množství)

- Výsledek: robotická paže zajišťuje vysoce přesný a spolehlivý pohyb, výrazně zvyšuje efektivitu a konzistenci na automatických výrobních linkách.

Technologický průvod:

Naše robotické paže jsou definovány přesným 5osým CNC obráběním. Tato metoda obrábění umožňuje vytváření komplexních geometrií z jednoho bloku materiálu, čímž zajišťuje vyšší strukturální integritu a přesnost pohybu.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

LV

LV

SR

SR

SK

SK

UK

UK

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

EU

EU

BN

BN

BS

BS

LA

LA

NE

NE

SO

SO

KK

KK