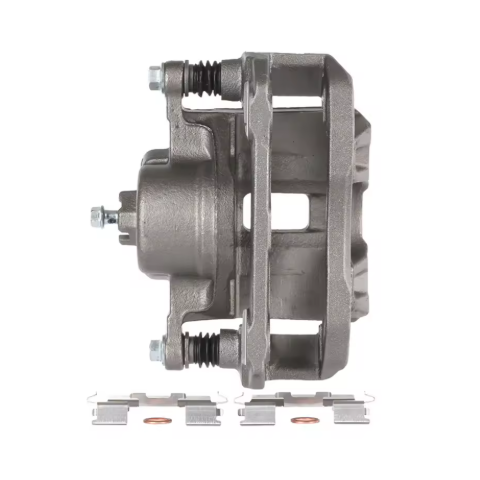

Custom CNC Machined Aluminum Alloy Brake Caliper

Engineered for excellence, our brake calipers are custom-made from high-grade aluminum alloy using advanced CNC machining. This process ensures exceptional strength, precise fit, and consistent performance for demanding applications. Let us manufacture the high-quality, precision parts your product line requires.

- Overview

- Inquiry

- Related Products

- Material:High-strength aluminum-silicon alloy (e.g., 6061-T6).

- Process:5-axis CNC machining, supported by automated grinding and inspection steps for consistency.

- Key Advantage:Optimized strength and weight reduction, suitable for high-performance and standard vehicles, improving braking responsiveness and energy efficiency.

- Precision:Precision machining ensures key bore and mounting hole accuracy, critical for alignment and function.

- Tolerance:Tight tolerances within ±0.05 mm for critical dimensions such as piston bores and mounting points.

- Surface Finish:Anodizing layer ≥10 μm (color options available), surface hardness ≥HV 800, or high-temperature powder coating.

- Prototype Lead Time:5-7 days.

- Mass Production Lead Time:4-5 weeks.

- Outcome:Reliable braking performance, reduced brake drag, and extended service life, meeting high safety standards for passenger and performance vehicles.

Process Flow:

Our brake calipers are defined by an integrated process of casting, heat treatment, and multi-axis CNC machining, ensuring structural integrity and dimensional accuracy.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

LV

LV

SR

SR

SK

SK

UK

UK

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

EU

EU

BN

BN

BS

BS

LA

LA

NE

NE

SO

SO

KK

KK