What Are the Latest Trends in Parts Manufacturing?

Industry 4.0 and Smart Manufacturing Integration

IoT-Driven Production Monitoring Systems

Bringing IoT tech into manufacturing has completely changed how we keep track of production processes, making it possible to collect and analyze data on the fly. Smart sensors and other IoT gadgets are constantly pulling information from different points along the manufacturing line. They tell us what's going on with machines, how fast things are being made, and even what kind of environment the equipment is operating in. When something starts acting funny in these monitored systems, operators can spot problems early before they turn into bigger headaches. Take automotive component makers who've adopted IoT solutions for example many report cutting down their downtime by around 30% because they catch issues before they shut everything down. For businesses in sectors like precision sheet metal work or auto part production, keeping those production lines running smoothly without interruptions means hitting delivery dates consistently while still delivering products that meet all quality requirements.

AI-Powered Predictive Maintenance Solutions

Predictive maintenance powered by artificial intelligence is changing how factories handle equipment upkeep, shifting from fixing things after they break to catching problems before they happen. When manufacturers feed historical data into smart algorithms, these systems spot when machines might fail next. This lets companies plan repairs ahead of time instead of scrambling during unexpected breakdowns, which cuts down both downtime and those expensive emergency fixes. Some businesses have seen real money saved too – around 20% less spent on maintenance overall while keeping machines running longer between services. Take General Electric for instance. They implemented AI-based maintenance across several plants last year. Their engineers noticed fewer production halts because technicians could address minor issues before they turned into major headaches. For sheet metal fabricators and other precision manufacturing shops, getting reliable operation from expensive machinery means staying ahead of competitors who still rely on old school maintenance approaches. The technology isn't perfect yet, but early adopters are already seeing tangible benefits worth considering.

Digital Twin Technology in Precision Sheet Metal Fabrication

In the world of precision sheet metal fabrication, digital twin tech has emerged as something manufacturers simply can't ignore anymore. Basically, it's when companies create a digital copy of their actual equipment or production line so they can run tests and see what might happen before touching anything physical. What makes this approach valuable is that factories can try out different setups and tweak parameters without wasting materials or stopping production entirely. Many shops report faster turnaround times after implementing these virtual models because operators spot potential problems early on. Some automotive suppliers specifically mention better part consistency when working with complex designs that require tight tolerances. Looking ahead, most experts believe digital twins will be essential for smart factories aiming to cut down on energy consumption while still meeting those ever-growing demands for custom parts across multiple industries.

Advancements in Material and Fabrication Techniques

Lightweight Aluminum Alloys for Automotive Parts Manufacturing

The auto industry is going through some major changes as manufacturers start using more lightweight aluminum alloys in their designs. These new materials bring several benefits to the table, like better gas mileage and overall improvements in how cars perform on the road. When cars weigh less because of aluminum parts, they consume less energy to move around something that matters a lot these days when everyone wants to cut down on carbon emissions. Plus, drivers notice faster acceleration and smoother handling too. Recent studies show that automakers are increasingly swapping out steel for aluminum components across various models. This switch makes sense for companies trying to build lighter yet still safe vehicles without breaking any of the tough environmental rules now in place.

Multi-Color Oxidation Treatments in CNC Machining

CNC machining shops are turning to multi-color oxidation techniques more and more these days because they make parts look better while actually making them last longer too. What happens is that special chemical processes form those colorful oxide layers on metal surfaces which serve double duty protecting against wear and tear while giving products that extra visual punch consumers love. Looking at recent sales data across manufacturing, there seems to be real interest in these color options since they produce effects regular painting just cant match. Take aerospace companies for instance who need lightweight yet durable components with distinctive looks. Same goes for phone makers wanting their latest models to stand out from competitors. Industry insiders we talked to say that when companies invest in these fancy finishes, customers tend to remember the brand and come back for future purchases.

Hybrid Approaches Combining 3D Printing with Traditional Methods

Manufacturing that blends 3D printing with old school fabrication methods is catching on because it makes production faster and better. Companies can take advantage of what 3D printing does well rapid prototyping and creating intricate designs while still relying on tried and true methods when making lots of products at once. When these two approaches work together, they cut down on expenses and shorten wait times, giving businesses an upper hand in making parts. Take aerospace companies for example. They've been using this mixed method to build lighter weight components with complicated shapes. This shows just how much room there is for new ideas and getting things done quicker in modern manufacturing processes.

Sustainability and Green Manufacturing Practices

Energy-Efficient Laser Cutting Technologies

Laser cutting tech has come a long way when it comes to saving energy and making manufacturing more eco-friendly. The biggest change? Newer laser systems that actually use less power during operation. Take fiber lasers for instance they consume around half the electricity of older CO2 models while delivering better results. For factory owners, this means real money savings on utility bills plus a smaller carbon footprint. Research shows these modern setups cut energy usage by about 30% compared to traditional approaches, which matters a lot as factories face increasing pressure to green up their operations. Beyond just meeting regulations, many companies are starting to see sustainability as part of their core business strategy rather than an afterthought.

Recycled Materials in Sheet Metal Production

Using recycled materials in sheet metal production cuts costs while being better for the planet. When manufacturers work with recycled metals instead of virgin ones, they cut down on mining operations that strip away natural resources. The Cradle to Cradle program helps verify if these recycled materials actually perform well and are environmentally sound. Looking at what's happening in the marketplace right now shows people want greener options. Recent surveys point to about a 20 percent jump in customers who actively seek out products made through sustainable methods. For sheet metal shops trying to stay competitive, incorporating recycled content makes sense both ecologically and economically as markets continue shifting toward sustainability.

Waste Reduction Through Rapid Prototyping

Rapid prototyping really helps cut down on waste because it lets designers keep tweaking their ideas without going through all the material costs that old school methods demand. Think about it this way: instead of building full scale models over and over again, companies can test small versions first. A lot of businesses have started adopting this method lately, especially in sectors where material costs run high. Some studies show waste levels dropping by around 20-25% when companies switch to these faster prototyping techniques. Looking ahead, new technologies like better 3D printing options promise even greater reductions in waste. For manufacturers trying to balance budgets while being environmentally responsible, rapid prototyping offers both practical savings and a smarter long term strategy for dealing with industrial waste problems.

Innovative Manufacturing Solutions from RMT Products

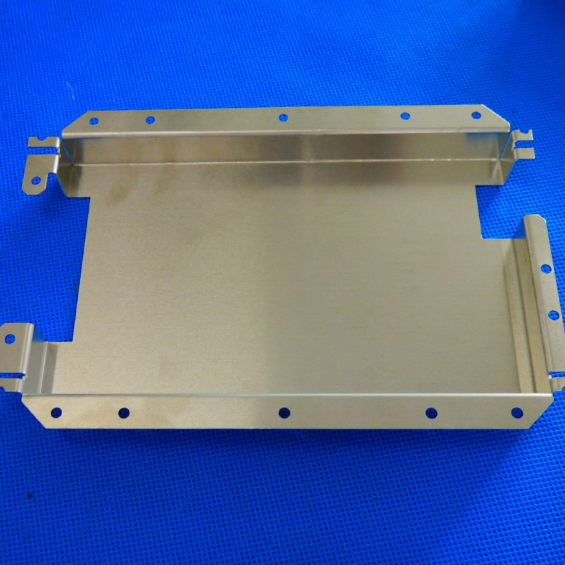

Sheet Metal Parts Production for Diverse Applications

RMT handles sheet metal production for all sorts of industries, showing just how adaptable they really are when it comes to manufacturing. The company works with various fabrication techniques including cutting, bending, punching, stamping and welding. These methods serve multiple markets from cars to planes and even electronic devices. Take car parts for example they need extremely accurate sheet metal work because safety standards are so strict in the automotive world. When we look at aircraft construction, sheet metal plays a critical role in building both strong yet light weight structures that can withstand extreme conditions. What sets RMT apart is their ability to customize solutions based on what clients actually need. Whether someone wants something standard or completely unique, RMT makes sure whatever gets produced fits exactly what the industry demands.

High-Precision Multi-Color Oxidation CNC Milling

When it comes to CNC milling, RMT really pushes the envelope on precision and quality workmanship. That kind of attention to detail keeps them ahead of the pack in manufacturing these days. What makes RMT stand out even more is how they've incorporated multi color oxidation techniques into their production流程. This gives customers extra options for customizing looks while making things look nicer overall. We're talking about stuff like car parts and electronic components here. The oxidation treatment does double duty actually enhancing both appearance and durability against rust and wear over time. Most people who have worked with RMT mention how impressed they are with both how good the finished products look and how well they hold up. This consistent feedback helps solidify RMT's reputation as a go to manufacturer in their field.

Custom Blue/Green Oxidation Aluminum Components

RMT has developed a special blue and green oxidation process for aluminum parts that's really catching on in the market right now. People want products that look good and work well, and this treatment delivers both. These colors do more than just make things look nice they actually help protect against rust and wear better than standard treatments. We've seen them used successfully in all sorts of places from car manufacturers looking for durable parts to tech companies wanting components that stand out visually. Our customers keep coming back because when they put these treated parts into tough conditions like saltwater environments or extreme temperatures, they perform where others might fail. Several major clients have shared how switching to RMT's colored oxidation made a real difference in product longevity and customer satisfaction across different industries.

Automotive-Grade Plastic Injection Molding Services

What really makes RMT stand out in the automotive field is their top-notch plastic injection molding work that delivers parts with exceptional precision and lasting durability. They check all the boxes when it comes to important industry standards like ISO 9001 quality management and RoHS environmental compliance. For car makers dealing with today's changing needs, this matters a lot since there's growing demand for components that are both light weight and strong enough to handle real-world conditions. The whole sector seems to be moving toward thermoplastics and composite materials these days, and RMT helps manufacturers keep up with that shift by integrating new materials that not only perform better but also happen to be friendlier to the environment in the long run.

Natural Oxidation Turned Parts for Industrial Use

Natural oxidation during manufacturing basically means applying a finish that makes aluminum parts last longer and resist rust while keeping them looking the same as before treatment. This comes in really handy for industries like aerospace and heavy machinery work, since these components need to hold up under tough conditions. Many top manufacturers have started using naturally oxidized parts because they know these treatments actually work to extend how long products stay functional, cut down on repair bills, and help meet those green manufacturing goals companies are pushing nowadays.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

LV

LV

SR

SR

SK

SK

UK

UK

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

EU

EU

BN

BN

BS

BS

LA

LA

NE

NE

SO

SO

KK

KK