The Importance of Precision in CNC Machined Parts

Defining Precision in CNC Machined Parts

Understanding CNC Machining Tolerances

Tolerances in CNC machining basically refer to how much a part can differ from its intended dimensions before it stops working properly or won't fit with other components. The amount of variation allowed determines whether a component will function correctly within systems like aircraft engines, surgical instruments, or car transmissions where precision matters a lot. Most manufacturers follow strict guidelines set by organizations like ISO or ASME when producing parts, because these standards help keep everything within acceptable limits for safety and performance reasons. Modern CNC machines are capable of creating parts with extremely tight tolerances down to around plus or minus 0.001 inch, though this depends heavily on what material is being worked with and how complicated the design happens to be. Getting familiar with these tolerance requirements makes a big difference in day-to-day operations, helping shops avoid costly mistakes and maintain reliable output even when running thousands of identical parts through their machines.

Role of CAD/CAM in Precision Engineering

Computer Aided Design (CAD) and Computer Aided Manufacturing (CAM) systems changed the game for precision engineering work completely. They let engineers check out designs on screen first, spot problems early, fix them digitally before cutting any metal, which cuts down on mistakes during actual production runs. When companies integrate both CAD and CAM together properly, they often see production times drop around 30% give or take depending on the project complexity. Most modern software packages now come packed with smart tools that help fine tune machine settings just right something absolutely necessary when working with those super tight tolerances needed in sheet metal fabrication jobs. Manufacturers who adopt these tech solutions regularly report better consistency across their CNC machining operations, meaning fewer rejects and higher quality parts coming off the line day after day.

Key Industries Relying on Precision CNC Machining

Aerospace & Defense: Demanding Zero-Failure Components

Aerospace and defense manufacturing demands something special from its components. We're talking about parts that must meet incredibly tight regulations where failure simply isn't an option. That's where precision CNC machining comes into play, helping create parts capable of surviving harsh environments. Think about the massive pressure changes and temperature extremes experienced during flights or when operating military equipment on the ground. The progress we've seen in aerospace technology really highlights how important precision machining has become. Aircraft wouldn't operate safely or efficiently without it, especially for things like turbine blades, fuselage sections, and those tiny but vital fasteners holding everything together. Without that level of exactness in manufacturing, many of these components just wouldn't function properly under real world conditions.

Medical Device Manufacturing: Life-Saving Accuracy

Precision matters enormously in medical device manufacturing because it literally can mean the difference between life and death. Components made using CNC machining techniques include everything from delicate surgical tools to complex implants, all of which need to hit exact specifications for them to work properly and keep patients safe. Regulatory bodies like the FDA require extensive testing procedures along with detailed records, making sure manufacturers don't cut corners when it comes to getting measurements right. Without this kind of precision, there's always risk involved. That's why CNC machining remains so important for creating medical devices that actually save lives rather than cause harm, something every manufacturer needs to take seriously if they want their products to succeed in the market place.

Automotive & Sheet Metal Fabrication Applications

The automotive manufacturing sector depends heavily on precision CNC machining when it comes to making those really important parts like engine blocks, transmissions, and various structural components. Sheet metal fabrication is just as crucial too, helping manufacturers produce parts that are both light weight and strong enough for today's cars. Most industry specs call for tolerances around plus or minus 0.005 inches so everything works properly together. Thanks to advances in CNC technology, factories can now crank out these exacting parts at scale. This has become super important for improving how efficient vehicles run and keeping them safe on the road, particularly with all the shift happening toward electric models and lighter building materials across the industry.

Technological Advancements Driving CNC Precision

5-Axis Machining for Complex Geometries

Adding 5-axis machining to the mix completely changed how CNC machines work, making it possible to create complicated shapes that just weren't feasible with standard 3-axis milling before. Traditional 3-axis machines are limited, but 5-axis CNC equipment moves the cutting tool across five axes at once, which means better accuracy and faster results overall. What makes this tech so valuable? Well, it cuts down on having to set up the machine multiple times during production runs while delivering smoother surfaces and much tighter tolerances too. The aerospace sector, car makers, and companies producing medical devices all stand to gain from these improvements since they deal with parts that demand extreme precision day in and day out. Shops that switched to 5-axis systems report real gains in productivity after implementing them, with some seeing up to 40% reductions in machining time for certain components.

Integration of AI for Error Reduction

Over the past few years, bringing AI into CNC machining has really changed how manufacturers handle errors and optimize their processes. These smart algorithms look at all sorts of data coming from machines as they work, spotting problems before they happen and fixing them on the fly. Shops that started using AI systems tell us scrap rates dropped around 25%, and their whole operation runs smoother now. Beyond just saving money, these AI tools actually speed things up without compromising quality. Take XYZ Manufacturing for instance they cut down their waste by almost a quarter after implementing one such system last year. For shops trying to stay ahead in today's competitive market, getting comfortable with new tech isn't optional anymore it's basically table stakes if they want to keep producing parts at world class levels.

Rapid Prototyping Services & Iterative Refinement

Rapid prototyping services are changing how manufacturers work these days because they let designers test out ideas much faster than traditional methods. With CNC machining, factories can tweak their prototype models again and again until everything fits just right for actual production runs. Some stats show this approach cuts down time getting products to shelves by around half, which gives businesses a real edge over competitors who stick to older techniques. Fixing problems in the design stage saves headaches later on when making thousands of units that might not work properly otherwise. Looking at what's happening across industries right now, CNC machining isn't just another tool anymore it's become essential for anyone wanting to stay ahead in today's fast paced world of product creation.

Benefits of High-Precision CNC Machining

Reduced Material Waste Through Exact Tolerances

CNC machining with high precision helps cut down on wasted materials because it hits those tight tolerances right from the start. For companies trying to go green, this tech makes a real difference since it cuts back on extra scraps and leftovers. Factories that switch to these precise methods usually see around 30% less waste, saving money at the same time as helping the planet. When parts are made exactly as needed, there's just no need to throw away all that extra stuff, so production becomes much cleaner overall. Many manufacturers have found this approach works wonders for their bottom line while keeping their environmental impact low.

Cost Efficiency in Mass Production

When it comes to manufacturing, high precision CNC machining can really cut costs, especially when making products in large quantities. The machines waste less material and take less time to complete each part, which naturally brings down what things cost to make. Keeping good quality standards while cranking out more units is a win for businesses. Some factories have actually saved around 20% on their operating expenses once they switched over to these advanced CNC methods. Better returns on investments happen because manufacturers get more bang for their buck. They spend money smarter and end up making more profit while still being able to grow their operations without breaking the bank.

Enhanced Product Reliability Across Sectors

Getting precision right with CNC machined parts makes all the difference when it comes to reliable products in different applications. When components are made with accuracy, products tend to last longer without needing constant fixes, which naturally makes customers happier. Take automotive manufacturing for instance many factories have seen their failure rates drop dramatically after switching to higher precision components. Better reliability does wonders for how people perceive a brand. Customers come back because they know what they're buying will work consistently over time. After all, who wants to deal with unreliable products when there's so much competition out there? Precision machining just makes sense both from a quality standpoint and business perspective.

Precision CNC Machined Parts in Industrial Applications

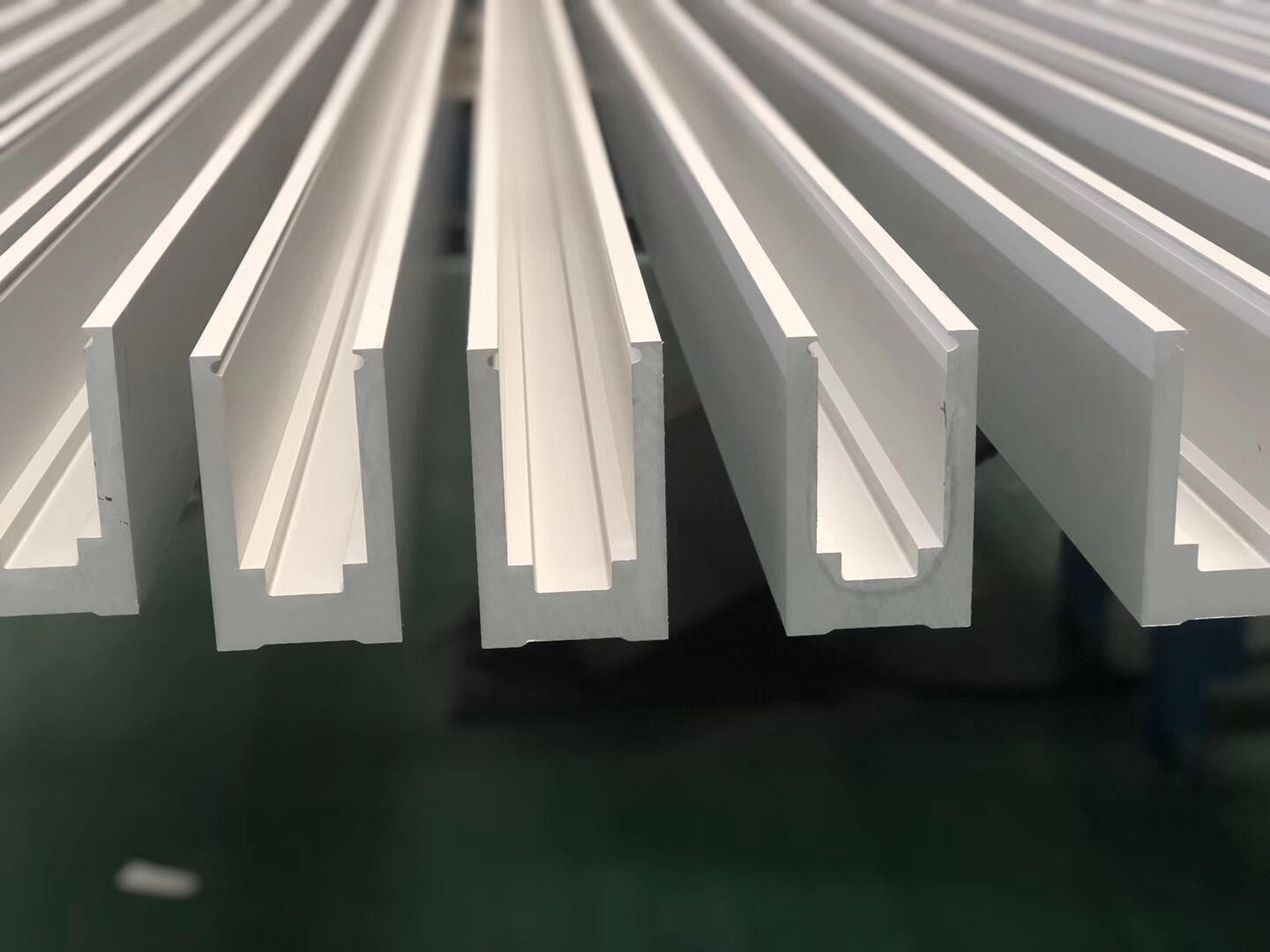

Custom Extruded Aluminum Profiles for Structural Integrity

Aluminum profiles made through extrusion play a vital role in keeping structures intact across both architecture and industry settings. When manufacturers use precision CNC machines, they can shape these profiles exactly how designers need them for particular projects. What makes this possible is that while aluminum stays light enough to handle easily, it doesn't lose strength or durability properties. That combination works wonders in construction, transportation equipment manufacturing, and even specialized machinery parts. The level of detail achieved when crafting custom extruded aluminum with CNC technology really stands out. Most clients find their projects end up meeting all those technical specs they originally wanted, sometimes exceeding expectations without breaking budgets.

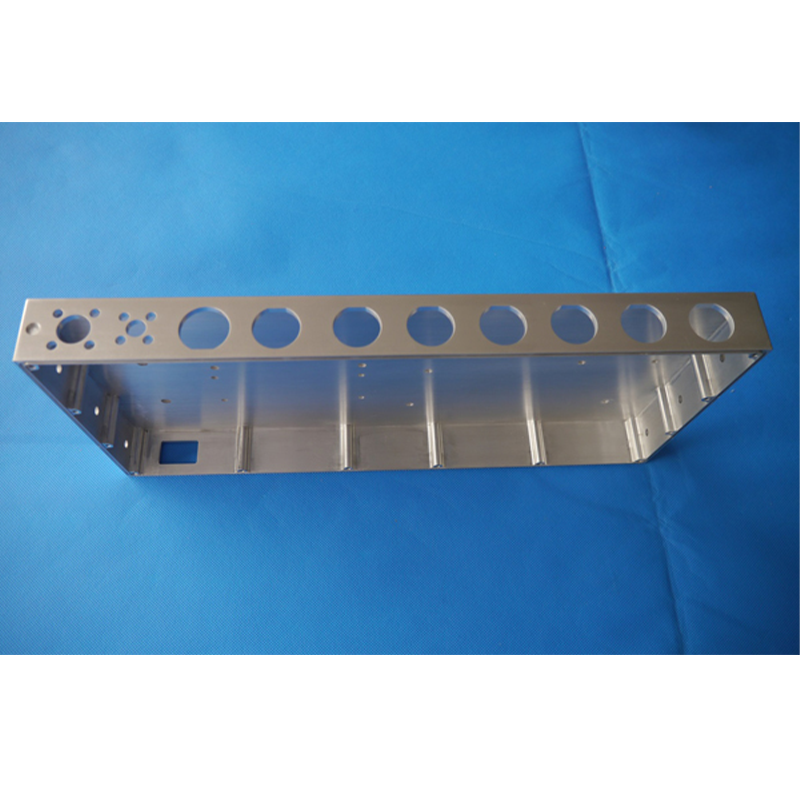

Wireless Infrastructure Components for 5G Networks

As 5G networks continue to roll out across the country, there's a growing need for components that can handle all this extra data traffic without breaking down. CNC machining plays a big part in making things like antennas and connectors with the kind of accuracy needed for faster internet speeds and better connections. The new 5G specs mean manufacturers now have to meet much tighter tolerances when building these critical pieces of infrastructure. Take those 150 sets of precision machined parts we've been producing lately - they're keeping our wireless systems running smoothly even under heavy usage conditions. This just goes to show how important accurate machining really is when it comes to advancing network tech and making sure everything stays connected properly.

Aerospace-Grade Electronic Instrumentation Parts

Precision matters a lot in aerospace work, particularly for those tiny electronic components that keep planes flying safely. A slight mistake or measurement error can actually spell disaster for both pilot and passengers down the line. That's where CNC machining steps in. These machines create parts that hit all the tough requirements set by aviation authorities, which explains why they're so vital for keeping aircraft dependable over time. Take those 180 sets of precision machined parts we've been talking about lately. They fit right into various aerospace applications because of how accurately they're made. And let's face it, no one wants to compromise on safety when millions of people rely on these systems every day.

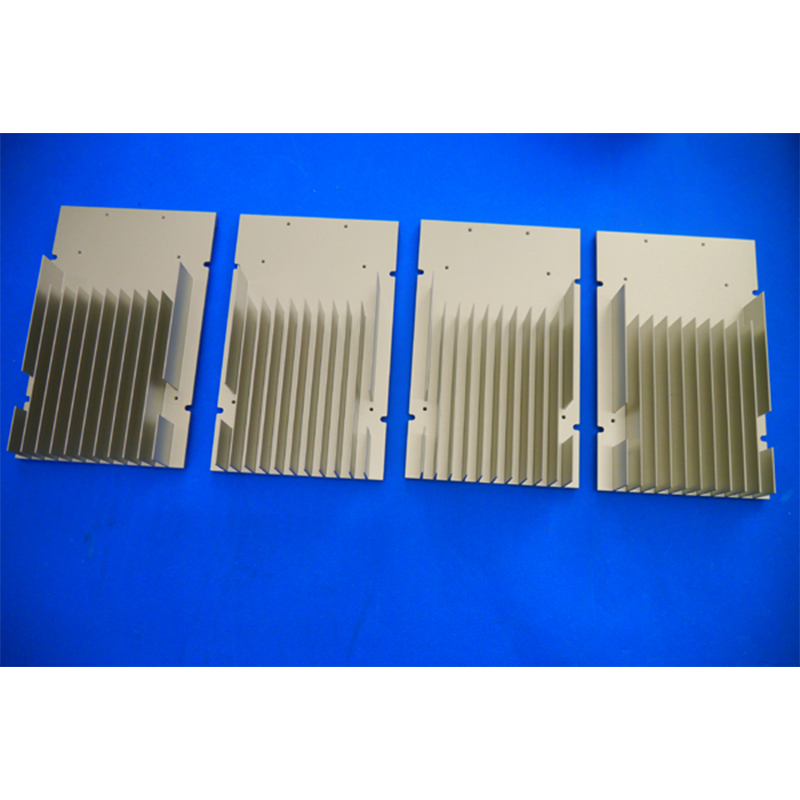

High-Performance Heat Sinks for Thermal Management

Heat sinks play a really important role when it comes to keeping electronics from overheating, especially since systems need to stay cool and work properly no matter what kind of environment they're in. When manufacturers make high quality heat sinks using CNC machining techniques, they get better fitting parts that actually do a much better job at cooling down equipment. How well these heat sink components perform has a direct impact on whether or not the whole system will keep running reliably over time, which is why getting the machining right matters so much. Take for example the 100 Sets Aluminum 6061 Precision CNC Machined Heat Sink products on the market today. These show clearly just how much difference proper CNC precision makes in creating effective thermal management solutions for all sorts of electronic devices.

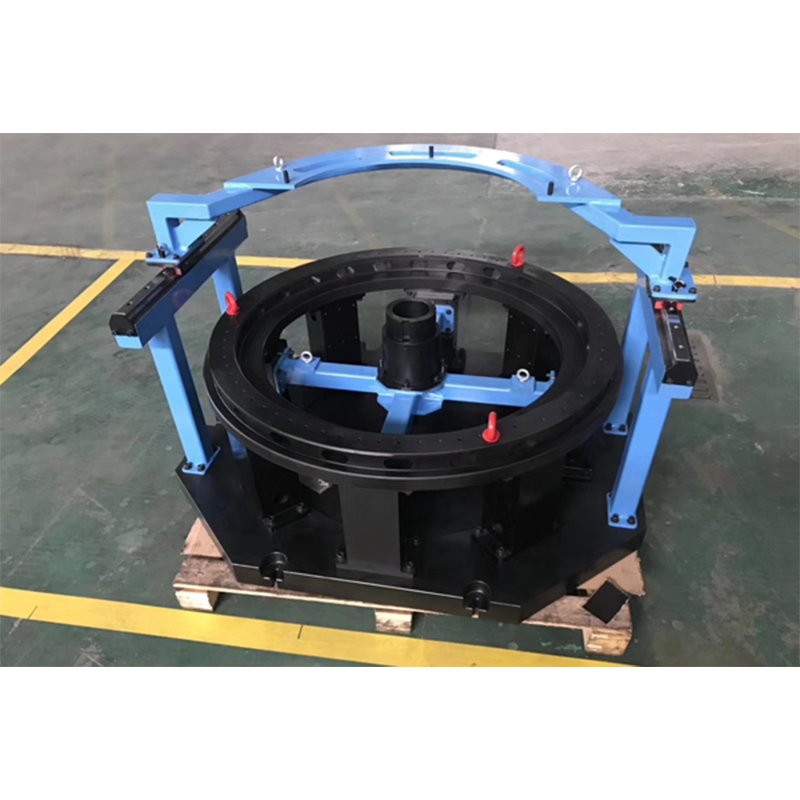

Hydraulic Power Systems with Tight Tolerance Requirements

For hydraulic power systems to work properly, they need components made within very tight tolerances. Without this precision, the whole system just won't perform reliably over time. That's where CNC machining comes into play. These machines create parts that actually stay leak free and keep hydraulic operations running smoothly. When we talk about precision here, it really affects how much energy the system consumes and what kind of workload it can handle day after day. Take a look at those 12 Sets of Precision CNC Machined Parts for example. They show exactly why CNC machining matters so much for hydraulic applications. The parts have to withstand high pressures while maintaining exact dimensions, something regular machining methods simply can't achieve consistently.

Ensuring Quality in CNC Machined Components

ISO Certification & Compliance Standards

Getting ISO certified provides a solid foundation for managing quality in CNC machining operations while keeping things standardized across the board. When businesses follow these global standards, they build up their reputation and give customers peace of mind about what comes out of their factories. Companies with ISO certification generally find themselves with more trusting customers and fewer problems running day to day operations. The fact that so many people recognize this certification shows how serious a business is about quality control from start to finish. Products end up meeting those tough industry requirements because everyone knows what needs to be done at each step along the way.

Advanced Metrology Tools for Precision Verification

Advanced metrology tools have become a must-have for manufacturers wanting to verify precision in their CNC machining operations. Coordinate measuring machines (CMMs), optical scanners, and laser measuring equipment all contribute to making sure parts fit within tight tolerances. The reality is these high tech instruments deliver measurements so precise they cut down on defective parts across production runs. For companies producing aerospace components or medical devices where even minor deviations matter, having reliable metrology systems in place isn't just helpful it's absolutely necessary. Industries ranging from automotive to consumer electronics now depend on this level of measurement accuracy to maintain product quality standards that customers expect.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

LV

LV

SR

SR

SK

SK

UK

UK

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

EU

EU

BN

BN

BS

BS

LA

LA

NE

NE

SO

SO

KK

KK