Benefits of Custom CNC Machining for Complex Parts Manufacturing

Understanding Custom CNC Machining

CNC machining, which stands for Computer Numerical Control, basically involves using computers to manufacture parts with extreme precision according to what clients ask for. When companies bring in this advanced tech into their workshops, they're able to craft intricate components that hit exact measurements while still fitting unusual design requirements. From cars to airplanes right down to medical devices, almost every industry relies on CNC work because getting things just right matters so much. Automotive manufacturers need those tight tolerances for engine parts, aerospace engineers depend on them for aircraft components, and hospitals require surgical tools made with absolute accuracy. That's why so many shops invest in good CNC equipment these days.

CNC machining has come a long way since the days when everything had to be done by hand. Back in those early days, operators spent hours adjusting machines themselves, and mistakes happened all the time because it was so hard to get things just right. When CNC technology finally arrived on the scene, it changed everything for manufacturers. Modern CNC systems now have all sorts of cool features like multi-axis movement and full automation that make production faster and much more accurate. The numbers tell an interesting story too. Industry reports suggest the CNC machining market will see about a 6.3% growth each year between 2020 and 2028. That kind of steady increase shows how important these computer controlled machines have become across different industries looking to boost productivity while maintaining quality standards.

Advantages of Custom CNC Machining

CNC machining brings something special to manufacturing when it comes to getting things just right. Most shops can hit tolerances around ±0.01 inches or so, which translates to about 0.127 millimeters. Some really advanced machines push even further, sometimes reaching down to ±0.0005 inches (that's roughly 0.0127 mm). Take Andrew Willing, a mechanical engineer who works on aerospace components. He swears by CNC for making those complicated parts that need to fit together perfectly in bigger systems. The bottom line is that consistent quality across all those parts matters a lot. And what's really cool? Manufacturers can create super detailed designs without worrying about losing that crucial level of accuracy throughout production runs.

CNC machining has found its way into all sorts of industries because it can create custom parts when needed. Take cars for instance - manufacturers rely heavily on CNC machines to produce everything from engine blocks to suspension components. These parts need to meet strict safety requirements, which CNC helps ensure through consistent quality control. When we look at airplanes, weight matters a lot. The aerospace sector depends on CNC to make super light but strong parts without compromising structural integrity. For doctors and surgeons, precision is everything. They count on CNC machined tools and implants that fit patients' bodies perfectly down to the millimeter. What makes this technology so special? It works with almost any material imaginable and handles complicated shapes that would be impossible with traditional methods. As manufacturing continues evolving, CNC remains at the forefront helping companies stay competitive while meeting ever-changing demands across different markets.

Key Applications of Custom CNC Machining

Aerospace Industry Applications

The aerospace field has seen major changes thanks to custom CNC machining, which delivers really precise results for important parts like brackets holding engines together and other aircraft components. Getting these measurements right matters a lot when it comes to keeping planes safe and running efficiently. We've noticed a big jump in how many companies want CNC made parts lately. Industry reports point to pretty strong yearly increases in this area. Why? Well, most folks working on aircraft know that CNC machines can hit those super tight specifications needed for aviation work. That means better performing planes and fewer safety issues down the road. Many manufacturers have switched over because they simply cant afford any mistakes anymore.

Medical Device Manufacturing

CNC machining is really important for making medical devices these days, especially when it comes to creating those super accurate surgical tools and implant parts. Medical manufacturing needs to follow all sorts of strict rules set by agencies like FDA and ISO, something that CNC machines handle pretty well. Take prosthetic limbs or orthopedic implants for instance they go through mountain of testing before ever reaching a hospital shelf. These components need to pass countless inspections because even the smallest flaw could mean serious problems down the road for patients. Recent upgrades in CNC tech have made things interesting though. We can now create much more complicated designs than before, including custom joints tailored specifically for individual anatomy. This means doctors can offer treatments that fit each person uniquely instead of relying on one size fits all solutions.

Automotive Components Production

Custom CNC machining plays a big role in making those exacting parts needed across the automotive sector - think engine blocks, transmission gears, even suspension components that need to hold up under real road conditions. The real value comes from how accurately these machines can cut metal time after time, something that matters a lot when we're talking about parts that literally keep cars running safely. With all this talk about electric vehicles and self-driving tech taking over, shops working with CNC equipment have had to adjust their approach. Many now work with lighter alloys and special composites that weren't common just a few years back. Some forward thinking manufacturers are already experimenting with combining traditional CNC methods with additive manufacturing techniques. While still in early stages, these hybrid approaches promise not only better quality control but also significant savings on material waste and overall production timelines.

Product Highlight: High Precision CNC Machined Parts

The benefits of high precision factory-customized CNC machining, especially for milling aluminum alloy cavity parts, are vast. These parts are specifically designed for industries requiring high accuracy and efficiency, such as electronics and aerospace. The customization allows for specific shape and dimension requirements, enhancing their effectiveness in intricate settings.

Processing and manufacturing turning brass CNC mechanical parts provide enhanced customization capabilities essential in various industrial applications. These parts are ideal for sectors that require precise mechanical components like connectors and fittings, allowing specific modifications according to different industrial needs.

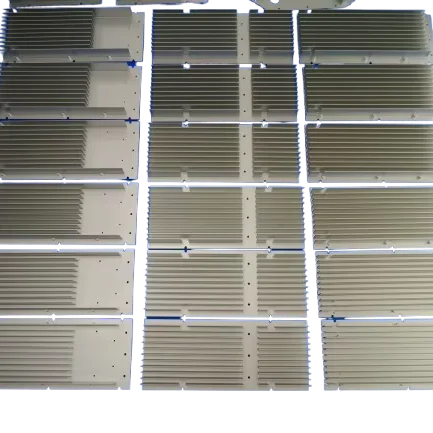

High precision CNC machining of aluminum alloy radiators offers significant design flexibility and enhanced performance for suppliers. This technique allows manufacturers to tailor radiator specifications to exceed standard cooling performance expectations in demanding electronic and automotive environments.

OEM custom processing using CNC five-axis machining is pivotal for manufacturing intricate automotive components with robust precision and scalability. This method guarantees high-quality replication of complex geometries and improves production timelines, maintaining exact standards necessary for automotive applications.

How to Choose a Custom CNC Machining Service

When looking for a good CNC machining service, there are several things worth checking out. First off, what kind of equipment do they actually have? Do they run basic machines or something more advanced like those fancy 5 axis mills and complicated turning centers that can tackle really detailed work with super tight measurements? These machines make all the difference when producing parts that need to fit together perfectly. Then there's the people factor too. A company might have great machines but if their team doesn't know how to operate them properly, everything falls apart. Skilled workers understand blueprints, spot potential issues before they happen, and know exactly how to set up each job for maximum results without wasting time or materials.

Knowing about production costs and how long things take matters a lot when picking a CNC machining service. Take time to look at those quotes carefully. What really counts is seeing how design complexity, material choices, and machining speed all tie together. A fancy design with unusual materials will typically cost more money and take longer to get done. For instance, parts made from titanium or requiring tight tolerances just naturally come with higher price tags and wait times. So when looking at different bids, don't just focus on what's cheapest. Think about whether the quoted time makes sense for your project schedule and if the total package actually represents good value for what you need produced.

Future Trends in Custom CNC Machining

Custom CNC machining is seeing major changes as automation and AI make their way into workshops across the country. When machinists start using these smart technologies, they notice better accuracy on the shop floor while mistakes from human operators drop off dramatically. Take tool path optimization for instance – AI systems analyze thousands of variables to find the most efficient cutting routes, which means less wasted material and faster turnaround times for jobs. What's really interesting though is how automated systems handle complicated operations all by themselves now. Machines can run through intricate designs overnight without constant supervision, something that would have required multiple skilled workers just a few years back. This kind of advancement lets manufacturing businesses grow their output capacity without having to hire dozens of new staff members at the same time.

The CNC machining sector has really started putting sustainability at the top of its agenda lately. Many shops are now going green by implementing various waste cutting methods. Some just recycle those metal shavings lying around while others work on making better cuts to save materials. Take Siemens and Bosch for example they've been leading the charge with these closed loop systems where scrap gets turned back into usable stock. Going green isn't just good for the planet either. Companies that embrace these practices tend to stand out in markets where customers increasingly care about how products get made. The bottom line is clear manufacturers who adopt sustainable approaches often find themselves ahead of competitors when it comes to attracting environmentally conscious clients.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

LV

LV

SR

SR

SK

SK

UK

UK

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

EU

EU

BN

BN

BS

BS

LA

LA

NE

NE

SO

SO

KK

KK