Advancements in CNC Machined Parts: Precision and Efficiency in Modern Manufacturing

Understanding Advancements in CNC Machined Parts for Modern Manufacturing

CNC machining, or Computer Numerical Control machining as it's officially called, represents a major leap forward for manufacturing these days. By letting computers take control of machines, this technology brings both precision and efficiency to the table. Manufacturers no longer rely solely on manual processes, which means products come out consistently every time without so many mistakes creeping in during production. For industries where exact measurements matter a lot, like making car parts, even tiny errors can spell big trouble for quality control. That's why so many shops have made the switch to CNC systems over traditional methods.

Looking at how technology has changed over time shows we went from those old punch card systems that required so much manual work to the advanced multi-axis machines available today. Modern equipment relies heavily on CAD/CAM programs to manufacture intricate components with remarkable precision. What makes this shift interesting is that it doesn't just improve what machines can do it actually embeds CNC technology right into the heart of sheet metal fabrication workflows. This integration means better quality products come off the line faster than ever before. As CNC machining keeps advancing, it's pretty clear this points to where the whole manufacturing sector is heading these days with automation becoming increasingly central to operations across industries.

CNC technology development has kept pace with rising quality demands across various industries including aerospace components, car parts production, and even smartphone manufacturing. When companies started adopting CNC machining processes, it was clear they wanted to meet those tough new standards that customers were expecting. Manufacturers faced real pressure from competition too. They needed machines that could work faster while still producing exact measurements down to fractions of millimeters. Today, as different sectors keep evolving, CNC remains crucial for keeping product quality consistent, cutting down on material waste during production runs, and getting more units out per day. We're seeing this play out everywhere now, especially with how quickly prototype designs get turned into actual products thanks to these advanced manufacturing methods.

The Role of Automation in CNC Machining

Bringing advanced robotics into CNC machining is changing how manufacturers operate on a daily basis. These robots take care of repetitive jobs that used to tie up workers all day long, while also speeding things up across the factory floor. When companies start using these automated systems regularly, their CNC machines can tackle complicated parts over and over again without breaking a sweat. This means fewer mistakes happen during production runs and there's less wasted material going into landfills. For sectors like aerospace or medical device manufacturing where even tiny measurement differences matter a lot, this kind of robotic precision makes all the difference between success and costly recalls down the line.

The manufacturing world has really embraced automated CNC processes these days, and for good reason. Companies see real savings on labor costs while cranking out more products at the same time. Plus, workers stay safer when dangerous jobs get handed over to machines instead of people. The truth is, automation does boost production efficiency quite a bit, and it makes workplaces much safer overall. Machines handle those risky operations that would otherwise put humans in harm's way. Some factories report around 20% higher productivity after going fully automated, which gives companies a serious advantage in this tough manufacturing market where everyone is fighting for every dollar saved and every product made faster than their competitors.

By integrating robotics and automation, companies can achieve higher precision and productivity, meeting the rigorous standards set by sectors like automotive parts manufacturing and precision sheet metal fabrication. Thus, automation is not just a technological trend but a necessary evolution in manufacturing that ensures both economic and operational advancements.

AI and Machine Learning in CNC Machining

Bringing AI and machine learning into CNC machining is changing how manufacturers operate day to day. One major benefit comes from predictive maintenance systems that actually know when machines might fail before it happens. These smart systems analyze data patterns and alert technicians about potential problems weeks in advance. For example, some factories report cutting their unplanned downtime by over 30% after implementing these technologies. The bottom line? Companies save money on emergency repairs while keeping production lines running smoothly through what used to be tricky maintenance periods.

Operational efficiency sees a remarkable improvement as machine learning algorithms meticulously analyze operational data. These algorithms identify opportunities to streamline workflows, increasing throughput and optimizing the overall manufacturing process. By examining patterns and anomalies, these systems provide actionable insights to refine operations and boost productivity.

Furthermore, AI facilitates real-time monitoring of CNC machined parts, ensuring thorough quality control and consistency in production outputs. This capability resolves issues promptly and maintains stringent quality standards, which are critical in industries demanding precision machining, such as the automotive parts and aerospace sectors.

Research shows that when manufacturers implement AI systems, they often see performance gains around 15% or more across their operations. This kind of boost really highlights how important AI and machine learning have become for staying ahead in the CNC machining business. With so much pressure on factories to get more done with less waste, companies are finding that bringing these smart technologies into their workflow isn't merely helpful anymore it's almost necessary for survival in today's market conditions.

Innovations in Material and Tooling for CNC Machining

New composite materials and stronger alloys are changing how CNC machines work, making it possible to produce parts that weigh less but hold up better under stress. Manufacturers can now craft components with much better strength compared to their weight, something that matters a lot in industries where performance and longevity count. The auto industry especially benefits from this progress, along with shops that specialize in cutting and shaping thin metal sheets precisely. Sheet metal fabricators report being able to meet tighter specifications while still keeping costs down thanks to these material improvements.

The latest cutting tools on the market, particularly ones with diamond or carbide coatings, have really changed how CNC machining works. They last longer and perform better than older tools did. When shops switch to these coated tools, they don't need to replace them as often which means less downtime for maintenance crews. Maintenance teams spend hours swapping out worn tools in many manufacturing facilities, so this reduction makes a big difference in overall productivity. For factories running 24/7 operations, these kinds of improvements matter a lot. Production lines stay running smoothly without unexpected stops, and the whole machining process becomes more efficient over time.

New materials and improved tooling are making a real difference when it comes to thermal stability and wear resistance, which means parts stay precise for longer periods and last much better overall. When CNC machines work with these upgraded materials and tools, they tend to run about 30% faster according to industry reports. The improvements we're seeing highlight just how important material science innovations have become in today's CNC world. Manufacturers are now able to push past previous limits in both rapid prototyping and full scale production runs thanks to these scientific breakthroughs.

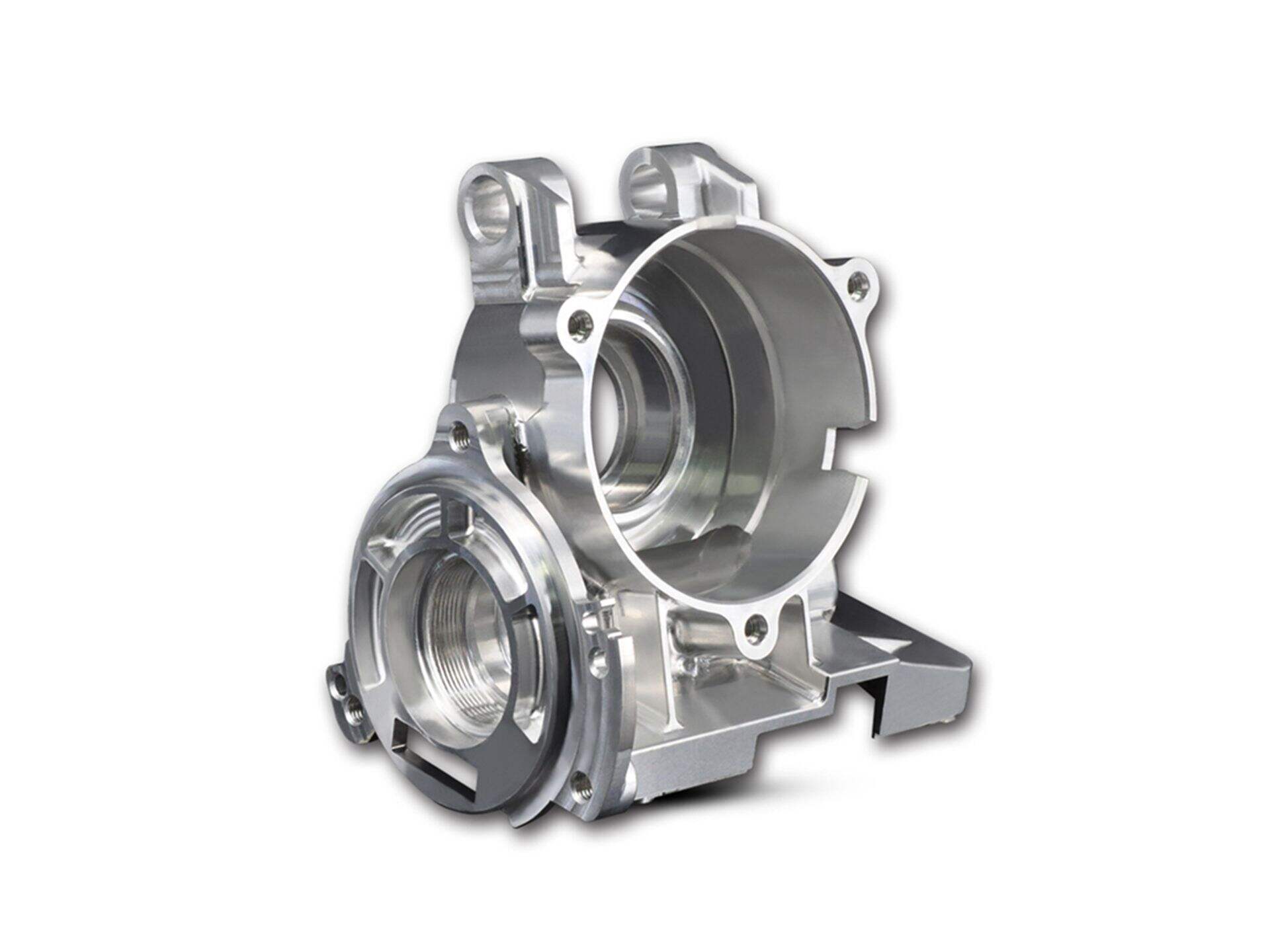

Product Section: Precision CNC Machined Hardware Parts

Parts made with CNC machining that can be customized are becoming really important across many different industries because they fit what clients actually need in terms of how they work and fit together. What makes CNC machining so valuable is that it produces parts with amazing precision which can then be adjusted for all sorts of sectors from cars to planes and even electronic devices. This kind of flexibility means manufacturers can create components right down to the last detail, which gives companies a real edge when they require something special that off-the-shelf products just cant handle. For small shops trying to compete with big manufacturers, having access to this level of customization often makes all the difference between winning contracts and losing out to competitors who cant match those specifications.

Keeping manufacturing standards top notch matters a lot when it comes to making sure those CNC machined parts hit all the regulatory marks and match what clients actually need. Good quality work means the parts will hold up over time and perform well even under tough conditions. Modern CNC machines let factories churn out consistent products that not only pass inspection but often go beyond what's required by the industry benchmarks. Many shops have found that investing in better equipment pays off through fewer rejects and happier customers down the line.

Modern CNC machines handle really complicated shapes and detailed designs, which is why they're so great for quick prototypes and adjusting production on short notice. The flexibility these machines offer combined with their ability to produce parts with extreme accuracy means CNC components are essential across industries that move at lightning speed. Think about automotive manufacturers needing custom engine parts overnight or sheet metal shops creating specialized enclosures for electronics. Companies using CNC tech don't just keep up with changing orders they actually stay ahead of them without sacrificing the tight tolerances required for serious engineering work. Many shops report being able to turn around jobs in half the time compared to traditional methods, all while keeping those critical quality checks intact.

CNC machined parts, such as the Precision CNC Machined Hardware Parts, provide tailored solutions for industrial and commercial applications. These customizable parts excel in precision and durability, making them an ideal choice for intricate manufacturing requirements.

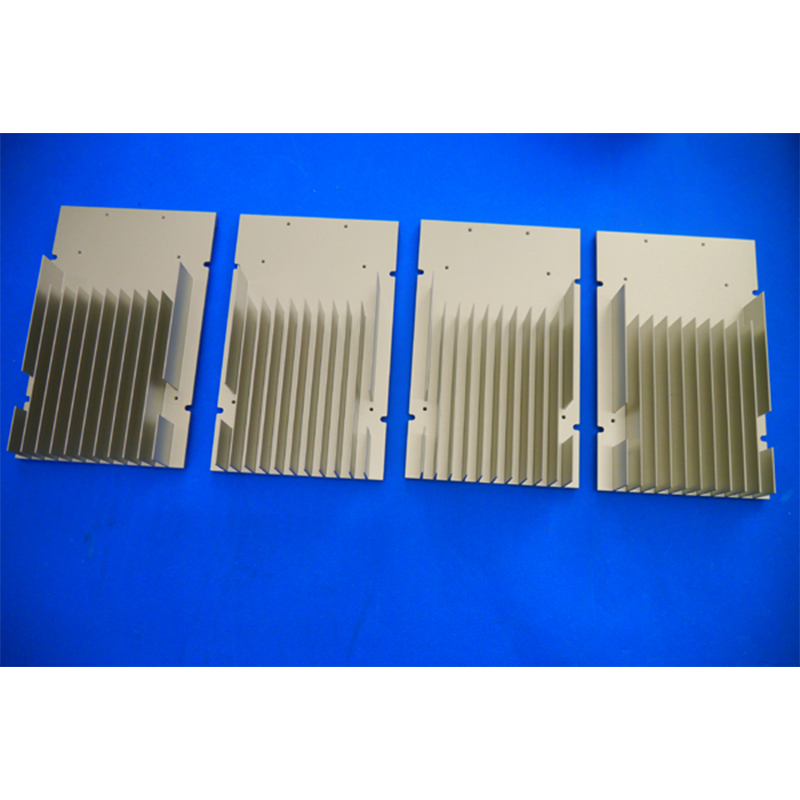

Product Section: 100 Sets Aluminum 6061 Precision CNC Machined Heat Sink

Aluminum 6061 stands out among materials for precision CNC machined heat sinks thanks to its impressive mechanical characteristics. The material delivers solid strength and lasting durability that make it well suited for dissipating heat effectively in electronic cooling systems. When components stay within their optimal temperature range, the whole system performs better and lasts longer before needing replacement or repair. Many manufacturers have switched to this alloy specifically because it handles thermal stress so well while maintaining structural integrity under demanding conditions.

How well these heat sinks hold up over time really matters because they're built to transfer heat efficiently from components that generate it. When manufacturers get the details right during production, it helps keep things running at safe temps instead of letting them cook themselves from inside out, which obviously extends how long electronics last before needing replacement. Most modern heat sink designs rely on computer controlled machining processes that cut metal with extreme accuracy. This means we end up with parts that fit exactly where they need to go without any rough edges getting in the way when installing them into different kinds of equipment.

When a manufacturer produces around 100 units at once, this shows just how scalable CNC machining really is. The ability to handle different sized orders makes these machines work well whether someone needs just a few prototypes or thousands for mass production. Most shops find they save money when buying materials in larger quantities too. Suppliers usually offer better prices when companies commit to bigger orders, sometimes cutting material costs by 15% or more. These savings help keep product prices competitive without sacrificing quality standards. Some businesses even reinvest those savings into better tooling which further improves finished part quality over time.

The Future Landscape of CNC Machining: Trends and Expectations

Bringing together additive manufacturing and traditional CNC machining represents one of those game changing developments we're seeing across manufacturing right now. The combination works wonders when it comes to custom work because it takes advantage of what each technology does best. CNC machines handle the precise cuts while 3D printers take care of the intricate shapes and internal structures. Manufacturers are finding this mix gives them much more freedom in their production runs. What used to require multiple setups or specialized tooling can now be done in a single process. Parts that would have been cost prohibitive just a few years ago are becoming standard fare for shops willing to invest in this dual approach.

The combination of CNC technology with Internet of Things capabilities is creating something new in factory operations. When these systems work together, machines actually talk to each other across the production floor, adjusting workflow as needed which boosts output numbers. Real time information flowing from sensors lets plant managers spot problems before they become major issues, saving both time and money when equipment breaks down unexpectedly. What we're seeing now with connected CNC machines shows just how serious manufacturers are about building workplaces where machines handle more tasks on their own while still maintaining quality standards throughout the entire process.

Looking ahead, manufacturers are expected to depend more heavily on data when making decisions and using real time analytics to fine tune their operations. Industry analysts predict that by mid decade, companies embracing these tech upgrades could see as much as a 30% boost in productivity across various sectors. What we're really seeing here is how cutting edge tools can completely change how things work in CNC shops and manufacturing facilities everywhere. When shops start bringing all these different trends together, it's not just incremental progress but actually represents a major shift in how business gets done. Efficiency gains become tangible while innovation becomes part of daily operations rather than something abstract or theoretical.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

LV

LV

SR

SR

SK

SK

UK

UK

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

EU

EU

BN

BN

BS

BS

LA

LA

NE

NE

SO

SO

KK

KK