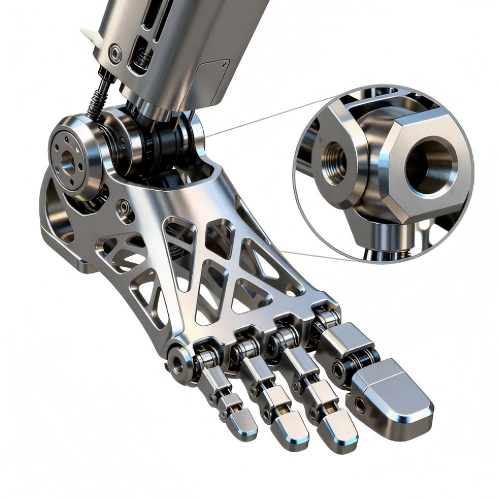

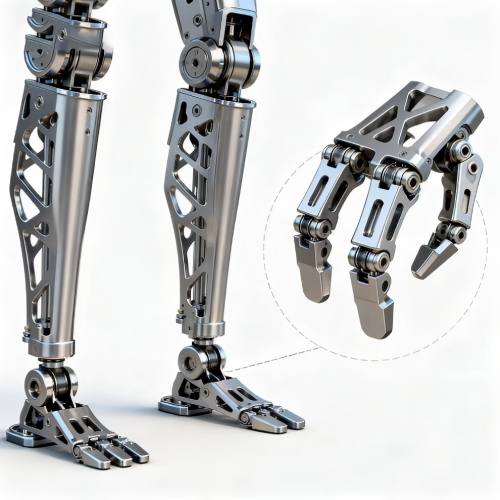

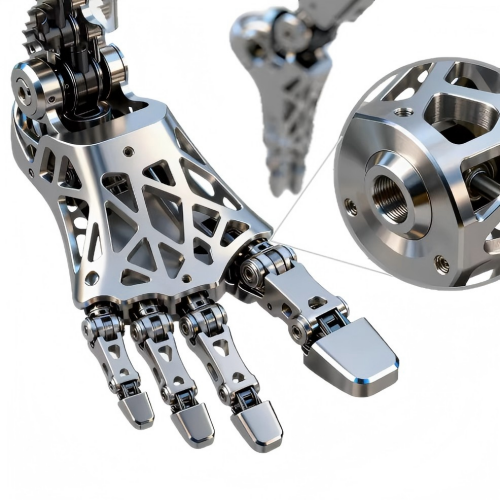

Custom CNC Machining Robotic End-Effector & Axial Components

Our custom 5-axis CNC machining service produces robust robotic end-effectors and axial components with micron-level precision. We work with materials like aluminum, titanium, and PEEK to create lightweight, high-strength parts that enhance automation performance. From prototyping to mass production, we ensure fast turnaround and reliability for demanding applications.

- Overview

- Inquiry

- Related Products

- Material:High-strength aluminum 7075-T6 or Titanium Alloy(Ti-6Al-4V).

- Process:5-Axis CNC Milling/Turning,enabling complex geometries in a single setup.

- Key Advantage:Exceptional rigidity and stability for precise force control and vibration damping,crucial for applications like precision assembly and material removal.

- Precision:Micron-level accuracy ensures dimensional perfection and operational reliability.

- Tolerance:±0.01 mm.

- Surface Finish:0.8 Ra,with options for anodizing or powder coating to enhance wear and corrosion resistance.

- Prototype Lead Time:5-10 days.

- Mass Production Lead Time:3-5 weeks.

- Outcome:High-performance components that enhance robotic automation precision,efficiency,and operational stability in demanding industrial environments.

Process Flow:

Our robotic end-effector components are manufactured through a precision 5-axis CNC machining process, ensuring high repeatability and compatibility with various robotic arms.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

LV

LV

SR

SR

SK

SK

UK

UK

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

EU

EU

BN

BN

BS

BS

LA

LA

NE

NE

SO

SO

KK

KK