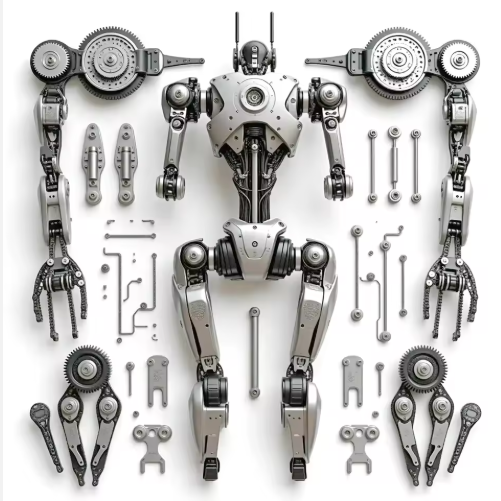

কাস্টম প্রিসিজন মেশিনিং অ্যালুমিনিয়াম অ্যালয় রোবটিক আর্ম

আমাদের কাস্টম-নির্মিত রোবোটিক বাহু দিয়ে আপনার অটোমেশনকে এগিয়ে নিন। উচ্চ-শক্তির অ্যালুমিনিয়াম খাদ থেকে তৈরি, এটি চাহিদাপূর্ণ শিল্প কাজের জন্য অসাধারণ নির্ভুলতা এবং দীর্ঘস্থায়ীত্ব প্রদান করে। ওইএম বা ইন্টিগ্রেটরদের জন্য উপযুক্ত যারা নির্ভরযোগ্য, উচ্চ-কর্মক্ষমতা সম্পন্ন অটোমেশন উপাদান খুঁজছেন।

- বিবরণ

- অনুসন্ধান

- সংশ্লিষ্ট পণ্য

- উপাদান: উচ্চ শক্তির 7075-T6 অ্যালুমিনিয়াম খাদ।

- প্রক্রিয়া: 5-অক্ষীয় সিএনসি মেশিনিং এবং নির্ভুল মিলিং।

- প্রধান সুবিধা: ওজনের তুলনায় আদর্শ শক্তি, উচ্চ দৃঢ়তা এবং ওজন কমানোর জন্য জটিল ডিজাইন তৈরি করার ক্ষমতা।

- নির্ভুলতা: পুনরাবৃত্তি অবস্থান নির্ভুলতা: ±0.05 মিমি (বন্ধ-লুপ সার্ভো নিয়ন্ত্রণ এবং উচ্চ নির্ভুলতার রিডিউসারের উপর ভিত্তি করে)।

- সহনশীলতা: ±0.01 মিমি।

- পৃষ্ঠের ফিনিশ: পৃষ্ঠের অমসৃণতা Ra 0.4, ঘর্ষণ ও ক্ষয় প্রতিরোধের জন্য হার্ড অ্যানোডাইজিং বা টেফলন কোটিং ঐচ্ছিক।

- প্রোটোটাইপ লিড টাইম: 1-5 দিন (নিশ্চিতকৃত 3D মডেলের উপর ভিত্তি করে)।

- বৃহৎ উৎপাদনের সীসা সময়: 2-3 দিন (অর্ডারের পরিমাণের উপর নির্ভরশীল)

- ফলাফল: রোবোটিক বাহু উচ্চ নির্ভুলতা এবং নির্ভরযোগ্য গতি প্রদান করে, স্বয়ংক্রিয় উৎপাদন লাইনে দক্ষতা এবং ধারাবাহিকতা উল্লেখযোগ্যভাবে বৃদ্ধি করে।

প্রক্রিয়া ফ্লো:

আমাদের রোবোটিক বাহুগুলি 5-অক্ষীয় সিএনসি মেশিনিং-এর মাধ্যমে নির্ভুলতার সঙ্গে তৈরি। এই মেশিনিং পদ্ধতি একক ব্লক উপাদান থেকে জটিল জ্যামিতি তৈরি করতে সক্ষম, যা উৎকৃষ্ট কাঠামোগত অখণ্ডতা এবং নির্ভুল গতি নিশ্চিত করে।

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

LV

LV

SR

SR

SK

SK

UK

UK

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

EU

EU

BN

BN

BS

BS

LA

LA

NE

NE

SO

SO

KK

KK